WHY JAYEM

Hello, Wishing you a good day,

We at JAYEM MANUFACTURING CO. humbly introduce ourselves as one ofthe oldest and most reliable Manufacturer of High Quality Automatic Equipment and Machinery for making Fly-Ash Brick and Pre-fab Concrete products such as, Interlocking Paving Block, Hollow Concrete Blocks, Curbstones, Grass Pavers etc. Since the year 1985.

Our world class Machinery and Technology are not only running successfully in India but also in Other Developing and developed countries with over 600 Machines Pan-India and Globally. We take pride in being a MAKE IN INDIA organization. Here is a video of a successfully Supplied and Installed Plant, for your reference, Please do share your feedback on the same.

Vibrating System

Twin-shaft Vibration box fitted underneath the Vibrating base ensures that the vibration is distributed uniformly in the range of vibrating table, thereby improves the uniformity and density of blocks, producing high quality product than before, using the same ratio of raw material, and effectively reduces the noise. Special design of fixing table improves the speed of making product and the accuracy of the size of product is consistent.

Control Panel

All procedure settings for production are completely automatic and controlled by PLC. Data in-outdevice can assure ideal man-machine conversation. The control system includes the advanced logical safety lock and trouble-diagnosis device that will point the trouble location promptly. Integrated control function can be used.

Material Feeding System

System compulsion type materials feeding system, ensures distribution of material in moulds evenly. Adjustable for all types of moulds.

Hydraulic System

System compulsion type materials feeding system, ensures distribution of material in moulds evenly. Adjustable for all types of moulds.

Why Jayem?

- 1) A dedicated team of Mechanical-Designers do intensive R&D through professional Software to bring you the best quality and reliable machines with highest efficiency.

- 2) Most Mechanical moving parts are replaced by hydraulics to eliminate wear and tear, dramatically reducing cost of maintenance, resulting in uninterrupted production cycle therefore, higher production rate.

- 3) Various Automation levels to suit your particular requirement and budget, With most equipment with Upgrading options to add Automatization.

- 4) Cement requirement reduced to as much as 5% which reduced the cost of production greatly, making it more profitable for you, without compromising on the quality of the Bricks and Blocks.

- 5) High efficiency and accurate Control panel making sure there are no accidents and hazards during operations, Perfect flow of Logic-control also reduces cycle time increasing the production rate even further.

- 6) A very sturdy and robust Hydraulic Power-pack ensures smooth functioning without any overload on the Machine, increasing the life of the Machine by decades.

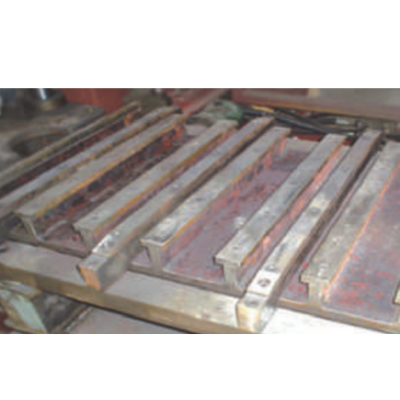

- 7) CNC Processed, duly hardened and Tempered Moulds have an amazingly long life and have an accuracy of + 0.1 mm.

- 8) Feeding the Mould evenly is one of the most important aspects of Casting Bricks/Blocks, Our feeder-box does exactly the same making sure all cavities are evenly fed to ensure high quality casting without any cracks and breakages.

- 9) A perfect equilibrium of Vertical-Vibration and appropriate Hydraulic Pressure is maintained by the machine to produce high density and incomparable finish.

- 10) Most of all, We are a 100% ‘Make in India’ organization, self-reliant and manufacturers since the year 1969, Making us one of the most trusted and reliable Manufacturers Globally.